Everything About Membrane Switch Over: A Comprehensive Guide for Beginners

Membrane switches are vital parts in contemporary electronic devices, using an unique user interface for customer interaction - membrane switch. Their layered building, including overlays and conductive traces, provides capability and toughness. Unlike typical mechanical buttons, membrane buttons provide a smooth design and adjustable choices. Recognizing their vital functions and advantages can change item style. The ins and outs of their application and layout factors to consider require more exploration.

What Is a Membrane layer Change?

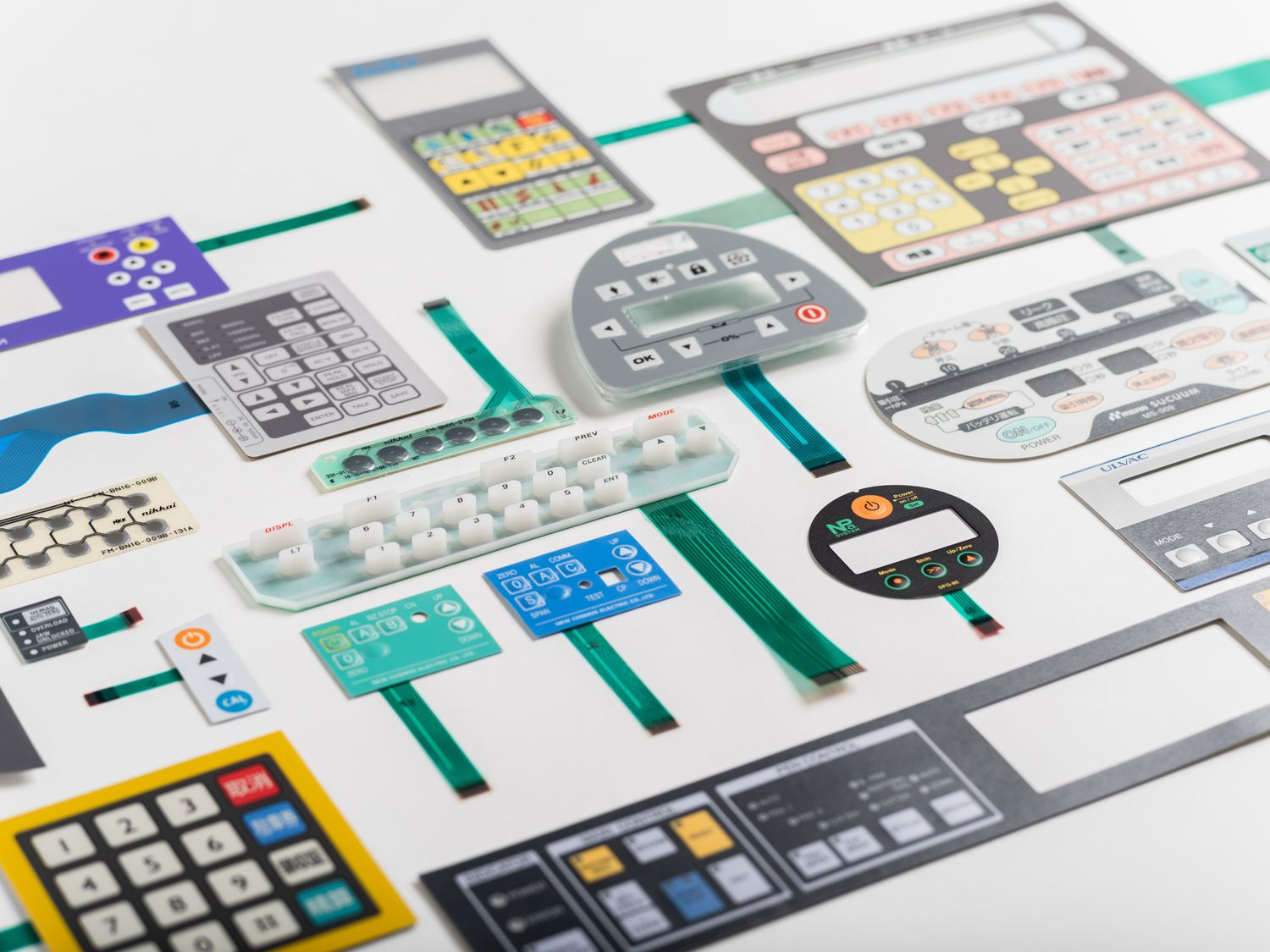

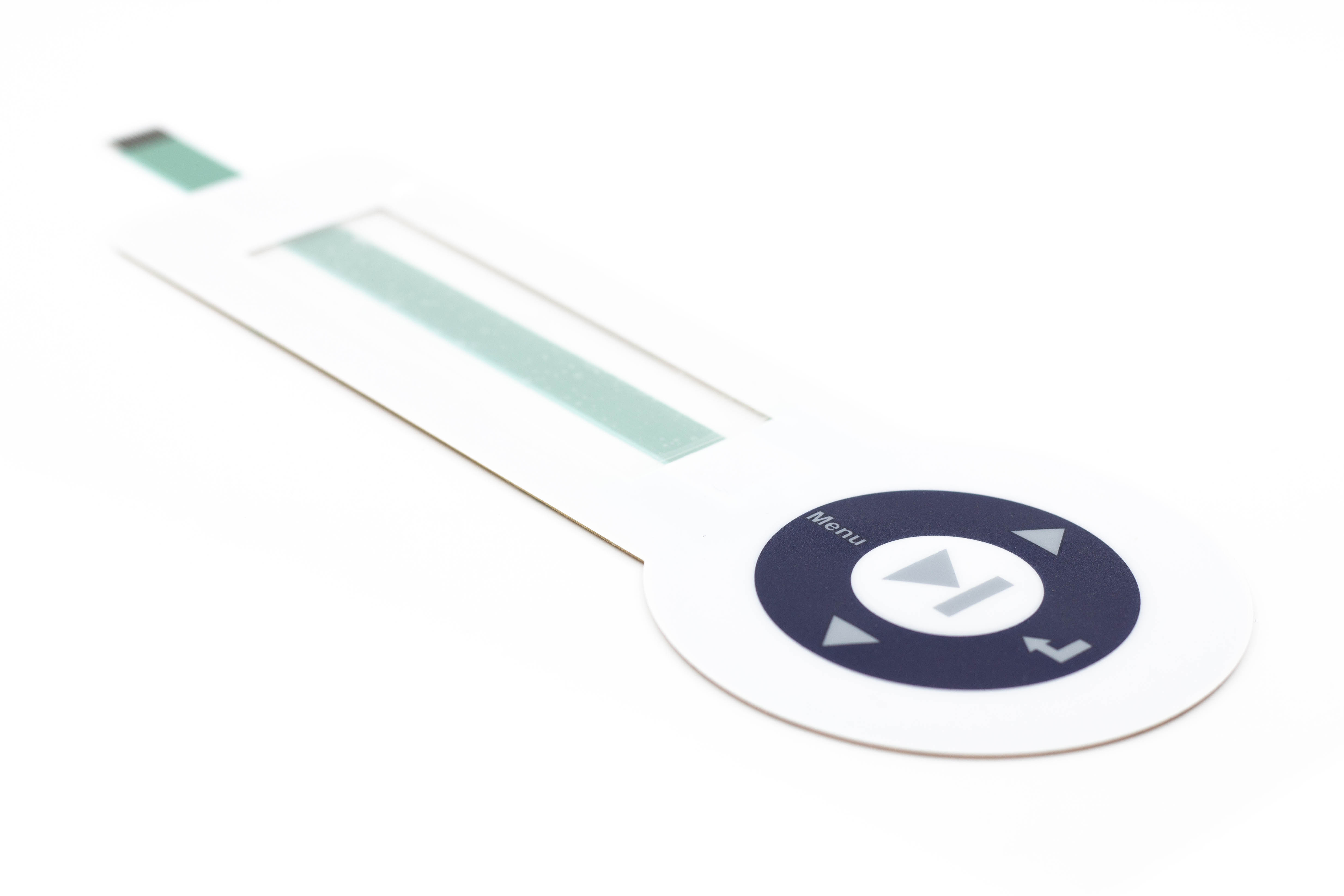

A membrane layer button is a kind of electric button that includes a versatile membrane layer layered over a published circuit board. This design permits for a streamlined and small user interface, typically utilized in different electronic tools. Membrane layer switches are frequently found in consumer appliances, medical tools, and commercial equipment as a result of their longevity and resistance to ecological factors.The construction usually includes numerous layers, such as visuals overlays and adhesive backing, which supply tactile comments and protect the circuitry below. The procedure of a membrane layer button is started when pressure is related to the surface area, finishing an electrical circuit.These buttons are valued for their adaptability, enabling personalized layouts and printed graphics that deal with certain interface. Their low-profile nature reduces room needs, making them excellent for applications where traditional buttons may not fit. In general, membrane buttons use a aesthetic and functional remedy for modern digital gadgets.

Trick Elements of Membrane Layer Switches Over

Membrane layer switches consist of a number of crucial elements that contribute to their performance and performance. The leading layer, called the overlay, gives the interface and is frequently published with symbols or graphics. Beneath the overlay lies a spacer layer, which separates the conductive components and stops inadvertent activation. The next crucial component is the visuals layer, which improves aesthetics and ensures the resilience of the design.Conductive traces, usually made from materials like silver or carbon, are published on the circuit layer. When pressure is put on the overlay, these traces enter into get in touch with, completing the circuit. Furthermore, a backing layer offers structural assistance and can be made from materials such as polyester or polycarbonate. With each other, these elements produce a trustworthy, straightforward user interface suitable for different applications, from home home appliances to commercial devices. Recognizing these components is important for anyone curious about membrane switch modern technology.

Just How Membrane Changes Job

Comprehending how membrane layer changes function is important for appreciating their widespread use in different devices. A membrane layer button runs through a series of layers, consisting of a graphic overlay, spacer, and a circuit layer. When stress is put on the overlay, it presses the spacer layer, allowing the circuit layer to make call and complete an electric circuit. This action sends out a signal to the device, motivating a response, such as activating a light or turning on a function.Membrane switches can be created with numerous features, including tactile responses, backlighting, and custom-made graphics, improving customer interaction. Their building and construction enables a sealed design, securing the inner elements from dust, dampness, and impurities. This durability makes them suitable for varied applications, from customer electronics to industrial tools. Generally, the simplicity and effectiveness of membrane layer changes contribute to their appeal in contemporary innovation.

Advantages of Membrane Switches Mechanical Switches

While mechanical buttons have long been a staple in many gadgets, membrane layer switches over deal distinct benefits that make them progressively appealing. One considerable advantage is their slim profile, permitting more portable layouts and better versatility in product development. In addition, membrane layer switches over attribute a consistent surface, which improves aesthetic allure and simplifies cleaning, making them ideal for settings where hygiene is critical.Another benefit is their resistance to dirt and dampness. Unlike mechanical switches, which can be jeopardized by environmental aspects, membrane layer buttons provide a sealed user interface that protects against impurities - membrane switch. In addition, membrane buttons commonly have a longer life-span because of less relocating components, leading to enhanced resilience and reliability.Cost-effectiveness is likewise a noteworthy benefit, as membrane layer buttons can be created wholesale with lower manufacturing expenses. These factors integrate to position membrane switches as a practical option to traditional mechanical choices in numerous applications

Typical Applications of Membrane Switches Over

Membrane layer buttons are extensively made use of in numerous markets, specifically in customer electronics and commercial control board. In customer tools, they provide a smooth, straightforward interface, while in industrial settings, they enhance sturdiness and performance. Recognizing these applications highlights the versatility and functionality of membrane switches in modern-day technology.

Consumer Electronics Instruments

As consumer electronic devices continue to develop, membrane layer switches have actually ended up being a prominent option for a range of devices due to their versatility and streamlined layout. These switches are typically located in smartphones, tablet computers, and remote controls, where room is minimal and looks matter. Their reduced account and customizable styles enable producers to develop easy to use user interfaces that improve the general individual experience. Additionally, membrane layer switches are usually made use of in appliances such as microwaves and coffee machine, giving instinctive control alternatives while withstanding dampness and dirt. The resilience and dependability of membrane changes make them appropriate for everyday consumer items, ensuring durability and consistent performance. In general, their assimilation in customer electronic devices reflects a mix of performance and modern style.

Industrial Control Panels

The applications of membrane layer changes extend past consumer electronics, finding significant usage in commercial control panels. These switches are preferred for their resilience and resistance to extreme settings, making them excellent for producing and process control setups. They supply a trustworthy interface for drivers to control equipment, screen processes, and readjust setups. Membrane buttons can be customized to fit details functional demands, integrating features like backlighting and tactile responses, enhancing customer experience. Their low-profile style enables combination into various devices, while their capacity to stand up to spills, dirt, and extreme temperatures warranties long life. In general, membrane layer switches add to secure and effective procedure in industrial applications, showing their flexibility and performance popular environments.

Considerations for Creating Membrane Layer Switches

When creating membrane switches, choosing the appropriate materials is vital to guarantee durability and functionality. Furthermore, recognizing layer arrangement methods can considerably influence the button's efficiency and individual experience. These considerations play an essential function in producing efficient and reliable membrane layer button layouts.

Product Selection Importance

Material selection plays a vital function in the layout and capability of membrane layer switches. The picked materials directly affect the switch's resilience, tactile feedback, and total aesthetic. Key considerations include the substrate, which must provide architectural honesty while allowing for versatility, and the graphic overlay, which needs to be resistant to put on and environmental variables. Conductive products ought to guarantee reliable electrical efficiency, while adhesives need to provide strong bonding without compromising the button's operation. Additionally, compatibility with making processes and end-user environments is vital; products should endure differing temperature levels, humidity degrees, and chemical exposure. Ultimately, suitable material option not only enhances the membrane layer button's efficiency but additionally adds to its longevity and user contentment, making it an essential element of the design procedure.

Layer Setup Strategies

Regularly Asked Questions

How Long Do Membrane Layer Changes Typically Last?

Membrane layer switches generally have a life-span of 1 to 5 million cycles, depending on usage and environmental conditions. Elements such as layout top quality and operating regularity considerably influence their longevity and total performance longevity.

Can Membrane Layer Switches Be Custom-made for Particular Styles?

Membrane buttons can indeed be customized to fit certain layouts, permitting diverse forms, colors, and performances. This flexibility enables makers to tailor these buttons to satisfy unique visual and operational requirements efficiently.

What Materials Are Used in Membrane Change Building?

Membrane layer switches are normally built making use of materials such as polyester, polycarbonate, and adhesive layers. These materials give durability, adaptability, and resistance to ecological variables, making sure the switches function successfully in different applications and problems.

Are Membrane Switches Immune or water resistant to Wetness?

Membrane layer switches can be created to be moisture-resistant, making use of specialized materials and coatings. Their water-proof abilities depend on construction quality and particular applications, making it vital to assess demands for ideal efficiency in various environments.

Exactly How Are Membrane Switches Repaired if Harmed?

Fixing broken membrane layer switches over usually entails changing the impacted layer or circuit. Service technicians might likewise apply conductive adhesive or make use of her comment is here specialized fixing packages, making certain capability is brought back without full substitute of the whole button assembly. Unlike standard mechanical switches, membrane layer buttons provide a sleek design and adjustable alternatives. A membrane layer switch is a type of electric switch that is composed of an adaptable membrane layered over a printed circuit board. The procedure of a membrane layer switch is launched when pressure is applied to the surface area, completing an electric circuit.These buttons are valued for their flexibility, making it possible for customized styles and published graphics that provide to particular customer interfaces. While mechanical buttons have actually long been a staple in many tools, membrane layer switches over offer distinct advantages that make them significantly appealing. Membrane buttons usually have a longer life-span due to less moving parts, resulting in enhanced durability and reliability.Cost-effectiveness is additionally a significant advantage, as membrane layer switches can be generated in bulk with lower production costs.